Table of Contents

ToggleWith the world more connected than ever through modern commerce, supply chains today are more intricate than ever. Goods travel between cities, nations, and continents before they arrive in the hands of final consumers. Along the way, several vendors—manufacturers, distributors, logistics companies, and subcontractors—have a key role to play in making sure products are distributed efficiently, on schedule, and in pristine condition. But with this complexity is an urgent problem: the danger of fraud and business inefficiencies due to untrustworthy or manipulative suppliers.

Supply chain fraud is not an accounting concern alone; it can also interfere with production timetables, devalue brand reputation, and even endanger consumers. Be it fake raw material, consignment delays, fraudulent description of product quality, or false invoicing, the impact is immense. The answer is vendor verification—a methodical, systematic process to substantiate the credibility, dependability, and genuineness of each business partner along the supply chain.

Comprehending the Risk Profile

Prior to delving into verification techniques, it is necessary to comprehend what kinds of risks vendors may pose:

Financial Fraud: Vendors can overcharge invoices, invoice for non-delivered goods, or practice price manipulation. In big operations, even trivial discrepancies can grow into huge losses.

Quality Risks: Low-quality materials or services can adversely affect the end product, leading to recalls, warranty claims, or consumer discontent.

Regulatory Non-Compliance: Vendors who do not comply with labor regulations, environmental protocols, or industry regulations subject companies to penalties and reputational loss.

Counterfeit Products: Particularly in industries such as electronics, pharmaceuticals, and high-end products, counterfeit goods by unverified suppliers can interrupt supply chains and endanger consumers.

Operational Inefficiencies: Vendors with track records of poor delivery, inventory control, or communication can imperil the supply chain, impacting customer satisfaction and operational expenses.

Knowing these threats makes it obvious that vetting vendors is not a voluntary exercise—it is a strategic imperative.

The Essence of Vendor Verification

Vendor verification is a multi-faceted process designed to assess a supplier’s credibility, compliance, and operational competence. It involves a combination of documentation scrutiny, background verification, on-ground evaluation, and digital intelligence to construct an all-around picture of a vendor’s reliability.

1. Legal and Corporate Verification

The initial step is to ensure that the vendor is a valid business entity. This entails:

- Corporate Registrations: Conducting a search of government records to verify the company’s registration, legal status, and ownership structure.

- Tax Compliance: GST, VAT, or other tax credentials verification ensures that the vendor is running legally and transparently.

- Licenses and Certifications: Some industries need certain certifications, like ISO standards, food safety licenses, or environmental permits. Making sure these are updated and valid minimizes compliance risks.

Validating this information helps organizations avoid fake or shell vendors that may otherwise cause serious financial and legal risks.

2. Financial Health Assessment

The financial health of a vendor has direct implications for its ability to consistently deliver goods and services. Validation in this area includes:

- Credit Checks: Reviewing credit history and open obligations to determine payment dependability.

- Financial Statements Review: Reviewing balance sheets, income statements, and cash flow statements to determine operation stability.

- Market Reputation: Knowing how other customers or business partners think about the vendor’s financial behavior can show submerged risks.

Financially stable vendors will less likely default, overcharge, or compromise, making it a more dependable supply chain.

3. Operational Capability Verification

Even a financially sound and legally compliant vendor may interfere with operations if it is unable to perform as promised. Operational verification emphasizes:

Supply Capacity: Determining if the vendor has the capacity to manage the demanded order volume without delay.

Delivery Track Record: Examining historical performance, such as lead time and on-time delivery percentages.

Technology and Infrastructure: Determining if the vendor possesses advanced tools to manage inventory, track orders, and coordinate logistics.

Operational verification ensures that vendors are capable of meeting the demands of a fast-moving supply chain.

4. Background and Reputation Checks

Sometimes the greatest risk is hidden. Vendors may have a history of unethical practices that aren’t immediately visible. Background checks help uncover:

- Litigation History: Past or ongoing legal cases can indicate operational or ethical issues.

- Customer Feedback: Speaking to other clients or reviewing reviews provides insight into reliability and service quality.

- Industry Reputation: Trade associations, trade organizations, and market references are used to confirm credibility.

This added layer of confirmation gives weight to the process, lowering the risk of working with a vendor that has an unsavory reputation.

5. On-Site Audits and Inspections

Physical evaluation is a very important part of vendor verification. On-site audits enable businesses to:

- Take a look at manufacturing facilities, warehousing, and logistics procedures.

- Confirm promises regarding capacity, quality control procedures, and storage conditions.

- Meet operational and management teams face-to-face, establishing a closer working relationship.

- Physical verification is usually the best method to guarantee that vendors live up to agreed standards, since records online cannot always provide the full picture.

6. Digital Verification and Data Intelligence

With the growth of digital supply chains, technology becomes increasingly instrumental in vendor verification:

- Digital Identity Verification: Software can verify business registration, ownership, and executive information online.

- Data Analytics: Tracking trends in payments, deliveries, and operational KPIs can detect anomalies that indicate fraud.

- Blockchain and Traceability Tools: Certain organizations use blockchain to trace products from source to final customer, providing vendor transparency and accountability.

Digital verification enables firms to monitor vendors in real time continuously, minimizing the risk of fraud even post-onboarding.

Implementing a Fraud-Proof Vendor Verification Process

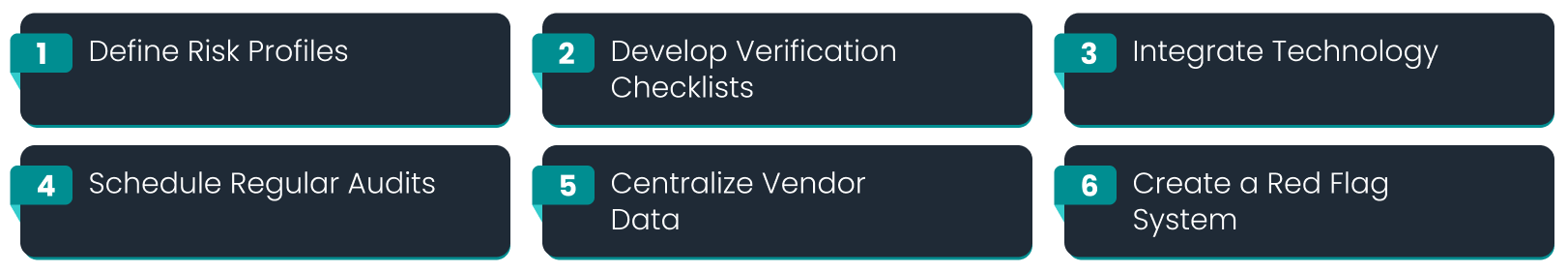

Creating a fraud-proof supply chain requires a structured approach that integrates multiple verification layers. Here is a recommended framework:

Define Risk Profiles: Categorize vendors based on their risk levels. High-value suppliers, critical material providers, and international vendors may need more intensive verification than local, low-value suppliers.

Develop Verification Checklists: Create a standardized checklist covering legal, financial, operational, and reputational aspects. This ensures consistency across all vendors.

Integrate Technology: Use verification platforms or APIs that automate background checks, document validation, and credit assessments.

Schedule Regular Audits: Verification is not a one-time activity. Schedule periodic reviews to ensure ongoing compliance and performance.

Centralize Vendor Data: Maintain a single source of truth for all vendor information. This improves visibility and allows for better risk management decisions.

Create a Red Flag System: Identify early warning signs such as delayed deliveries, discrepancies in invoices, or negative customer feedback, and escalate them promptly.

The Strategic Advantage of Verified Vendors

Beyond fraud prevention, vendor verification offers strategic benefits:

- Enhanced Supply Chain Reliability: Verified vendors are more dependable, reducing delays and production bottlenecks.

- Stronger Partnerships: Vendors that undergo verification often feel a stronger commitment to quality, fostering long-term collaboration.

- Regulatory Compliance: Ensuring that vendors meet all legal and industry standards minimizes the risk of penalties and audits.

- Risk Mitigation: Companies can proactively address vulnerabilities, reducing financial, operational, and reputational risks.

- Data-Driven Decision Making: Verified vendor databases allow procurement and supply chain teams to make informed decisions quickly, especially in fast-moving industries.

Conclusion

In an era of increasingly complex and globalized supply chains, vendor verification is no longer optional—it is essential. A comprehensive, multi-layered approach that combines legal, financial, operational, reputational, and digital verification can create a fraud-proof supply chain. Companies that prioritize verification gain more than just risk mitigation; they achieve operational resilience, regulatory compliance, and strategic advantage.

Ultimately, supply chains are only as strong as the vendors within them. By investing in robust vendor verification, businesses can ensure that every link in the chain is trustworthy, efficient, and aligned with organizational goals. In doing so, they not only protect their bottom line but also safeguard their brand, their customers, and the integrity of the entire supply network.

Leave a Reply